You have 0 items in your cart.

The measures related to combating the corona pandemic lead to a new reflection on the private retreat. Homeowners appreciate the garden to make their everyday private life attractive despite the restrictions. More and more swimming pools are being built on their own land, as natural pools, liner pools or slab pools. Swimming pools based on plastics processing are an alternative that has been proven for years. The process heat technology for welding the plastic membranes or welding with welding wire for plastic sheets is therefore of great importance. Being able to use the ideal machine for the respective purpose makes work processes easier, faster and safer to implement. The extensive HERZ assortment of heat technology machines from European production, with headquarters in Neuwied in Rhineland-Palatinate, allows pool construction to always make the right choice.

Natural pond or natural pool, HERZ Mion welds optimally

The natural shape of the ground and its secure covering with plastic tarpaulin require special know-how when cutting and welding swimming ponds.

The Mion hot wedge welding machine scores with its smallest design, which makes it particularly user-friendly. The welding temperature on the hot wedge can be electronically regulated, as can the contact pressure, which is built up via two counter-rotating transport rollers and thus optimally “keeps the plastic membrane on track”.

Especially when building natural pools, with practically loose ground, the Mion allows you to work quickly and safely with high heat transfer for maximum welding performance on the plastic film.

Welding thermoplastic tarpaulins securely in the membran pool

For over 50 years, HERZ heating technology has been part of the range of machines used by demanding plastics processors. Not only on the roof, in industry, but also in the construction of swimming pools in tarpauline construction. Here, the HERZ Planon, as the smallest hot air welding machine for welding thermoplastic tarpaulin materials, maintaining its leading, user-friendly role for many years. With its proven and robust technology, with setting of speed, temperature and air volume via potentiometer as well as the welding widths of 20, 30 or 40 mm, it is well equipped for perfect results. A machine variant enables the digital setting of temperature and speed.

Chassis, motor housing and welding nozzle form a compact technological unit weighing only 15 kg, which on the one hand makes the Planon unmistakable and on the other hand contributes to unsurpassed handling during the manufacturing process.

Plate pool and ExOn 1, welding at its best

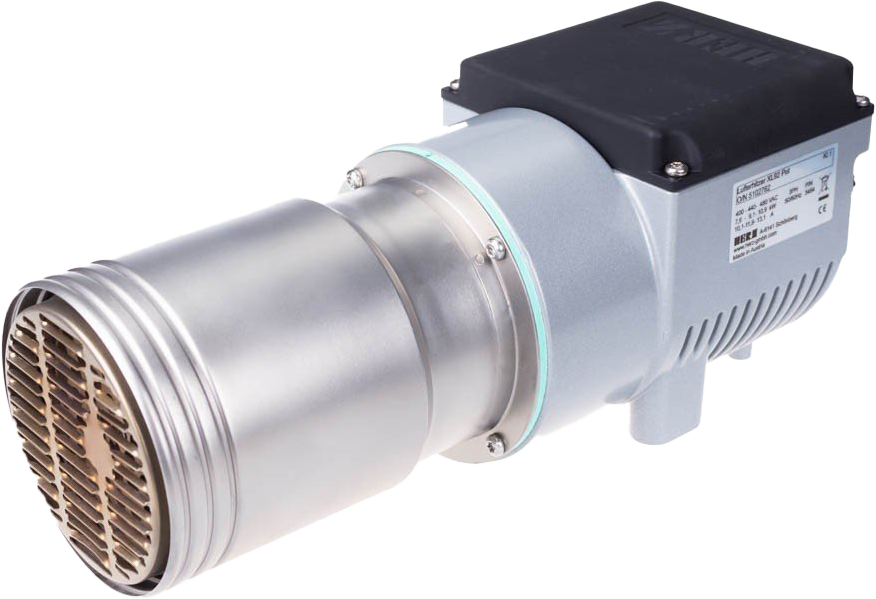

With the hand-held welding extruder ExOn1, the plastic parts of a plate pool can be perfectly joined using the plastic welding wire.

Equipped with patented temperature detection - directly in the melt - the best possible temperature control for plasticizing at the welding point is given. In this way, the plastic materials, e.g. PE-HD, PP or PVC welds with welding wire of the same type to form a homogeneous structure. With its output of up to 1.1 kg / h, with separately controllable air and mass temperature and the 360 degree adjustment of the welding shoe, the ExOn1 with its weight of only 5 kg is ideally equipped for a perfect welding result when building plate pools.

Finding the right answers with HERZ

However, swimming pool construction based on plastics does not only require powerful welding machines from a variable range of devices. There is also a demand for accessories such as nozzles, heating elements, pressure rollers, seam testers and edge planings.

Once the swimming pool has been completed, the skilled processor uses his quality control to ensure perfect work results. For this purpose, HERZ offers the control system of the future with the PD-240 dry leak detector. With the battery-operated leak tester, the complete test system is kept in a handy system case. As a further proven test method, test bells are available as vacuum test systems in the range.

If the keyword “welding” is used in the construction of plastic swimming pools, whether with tarpaulins or panels, HERZ-Wärmetechnologie offers an assortment with convincing quality standards.